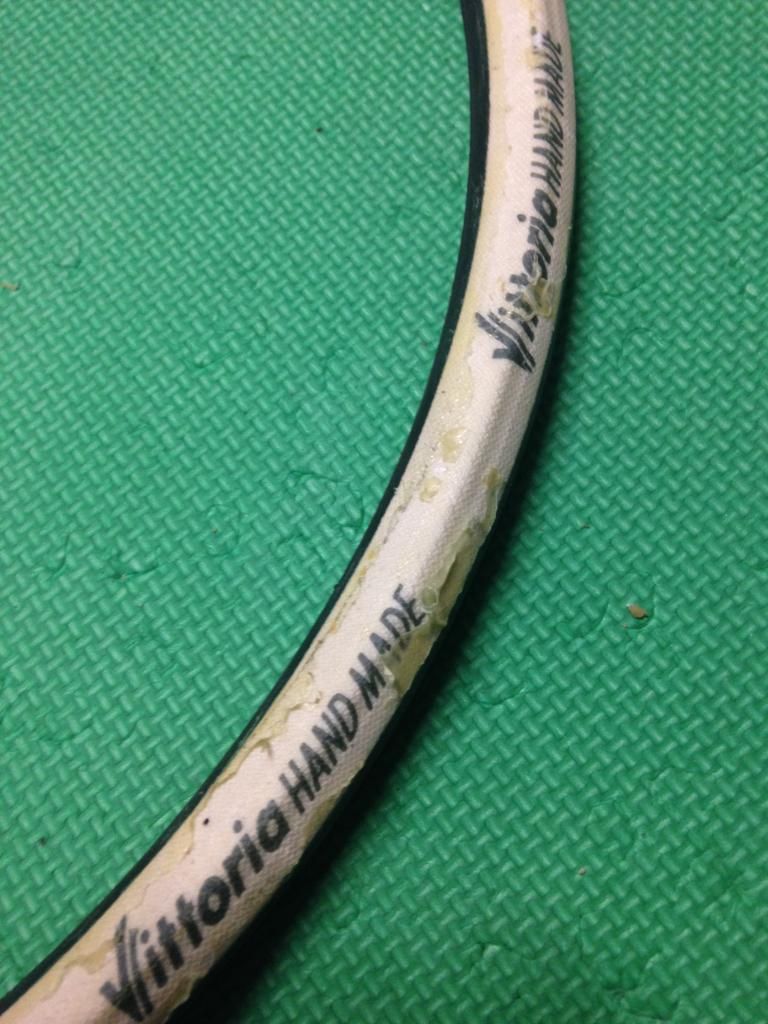

I would also like to add, although vittoria cx and sc are good for the money the veloflex are nicer. You may argue they aren't worth the extra dosh, but they are the easiest tyre I have ever mounted and well made. They have this ability to stretch like an elastic band when mounting.singlespeedscott wrote:The tread on the Challenge tyres I have used are infinitely straighter then any Rally's. Not knocking the Rally's. I think they are good tyre for the money they just never seem to be straight.Causidicus wrote:Never found Rally to be inconsistent but having said that, don't see them very often as most people only carry them as a ride home spare. I guess it comes down to what you think is inconsistent. Rallys that I've seen aren't really inconsistent at all but some people might think they are if they are used to machine manufactured tyres. Try and find a laser straight tread strip or millimetre perfect carcass on any hand made FMB, Dugast, Veloflex, Vittoria or Challenge. Simply doesn't happen, and simply doesn't matter.

I suppose it is like a balance scale, price verses quality, some favour one over the other.